The POWERFLUSH Series

SUPERIOR FLUSHING AND PRESSURE TESTING machines for tubes and hoses

The POWERFLUSH series, born in 1995, offers superior liquid cleaning, flow/pressure testing, and dry blowing for high-volume production up to 4000 bar.

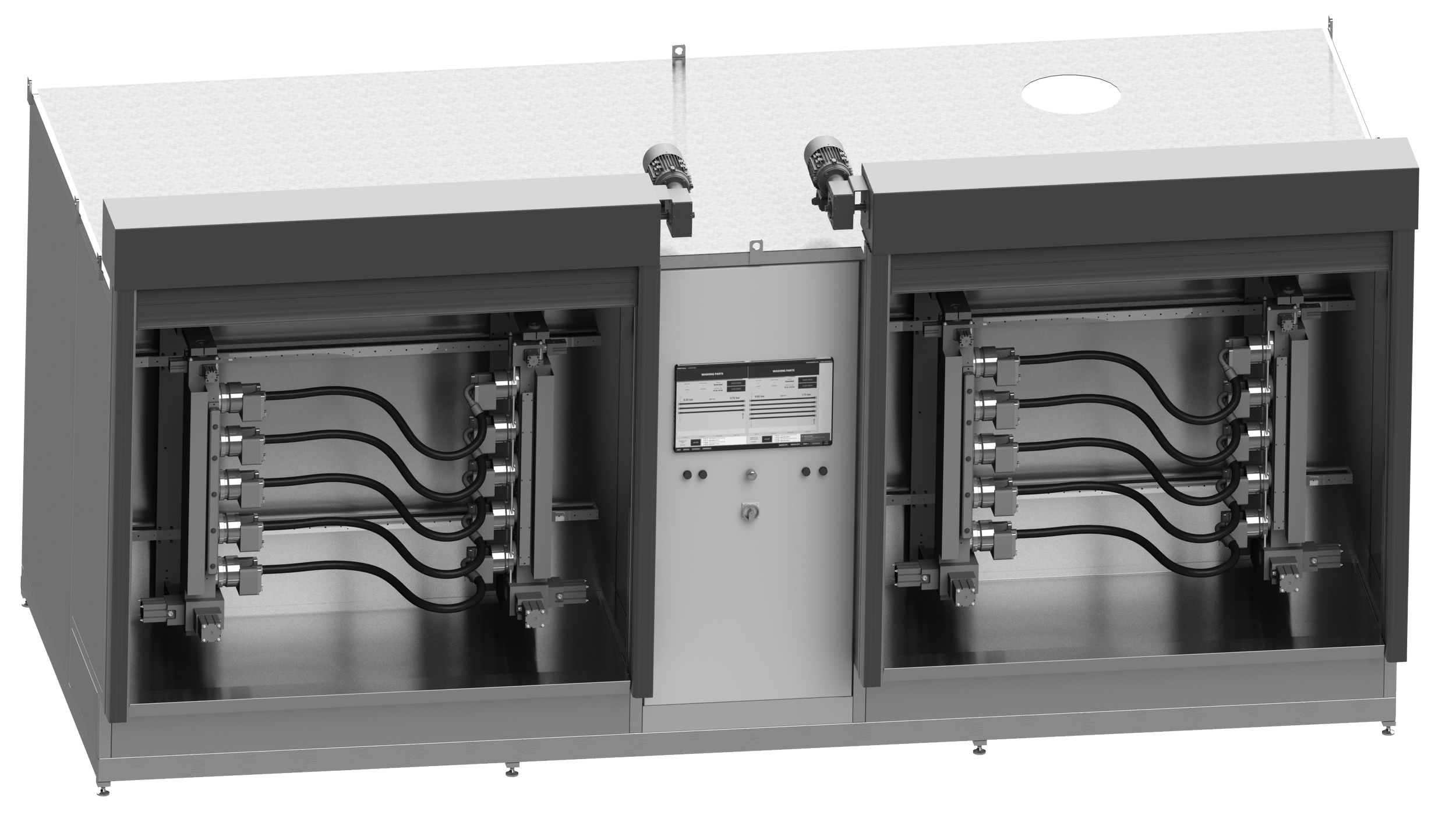

The FP-10-8100 can be designed for single or twin stainless steel chamber applications, with up to 10 positions for parts. These machines use our own quick-change sealing tools for sealing, integrated into vertical or horizontal fixtures.

Using electric roll-up doors, the operator simply loads the parts and presses start. The parts are sealed automatically, the door closes, and the cycle begins. The flushing cycle is fully adjustable in the ARC software, where the flow direction can be changed to create turbulence, further aiding the cleaning process. After flushing and pressure testing, the parts are dried using filtered air.

POWERFLUSH FP-10-8100 with twin chambers and 5+5 vertical flushing and pressure testing channels

For flushing only, we offer a stand-alone solution with quick connections for 2” hoses (flush-return-air). The FS-100 is a complete base machine with pumps, tank, filtration, and HMI. It can be delivered complete with custom tooling or connected to your own existing setup.

If you need to flush straight tubes, the revolving R-500 is your choice. Available for tube lengths of 200 – 1800 mm with diameters of 8 – 25 mm, this machine is normally used for cleaning stainless steel or aluminium tubes after end forming.

POWERFLUSH FS-100 stand-alone flushing machine

Standard features

| HMI | ARC ©, 24” touch-screen |

|---|---|

| Flushing | Directional, fully adjustable cycle |

| MAX PRESSURE | 4000 bar |

| Pressure test | Pressure drop monitoring |

| Filtration | Double filtration for water + air filtering |

| REMOTE SUPPORT | Yes (via ethernet, 3G/4G or WiFi) |

| Sealing | Manual, pneumatic or hydraulic |

| SCANNER | Barcode scanner for production orders, etc. |

ACCESSORIES & EXTRAS

Scrap box with light barriers

Dedicated multi-fixture for complicated geometries

Label printer

RFID login

The POWERFLUSH tank is equipped with heaters, insulation, overflow control and air/water separator

POWERFLUSH R-800 revolving 8-position flushing machine for tubes

ARC CONTROL SYSTEM

All machines from LANTZTECH use our in-house developed control system, ARC, enabling advanced features in a simple and easy-to-use HMI.

The ARC control system is built on an industrial PC and EtherCAT bus, featuring a large touch-screen display. The HMI presents clear textual and graphical representations of the machine’s operational status and cycle progression. Cycle steps are shown with distinct visual indicators (red/green), giving the operator a straightforward and informative overview.

With ARC, detailed statistics is a standard feature, facilitating in-depth performance monitoring. Furthermore, ARC’s flexible data communication capabilities enable seamless integration with various data management systems.