The CrimpER Series

OUR HOSE CRIMPING MACHINES HAVE BEEN MANUFACTURED AND REFINED FOR OVER 35 YEARS

The fully electric crimping machines from LANTZTECH for hoses and tubes offer rapid and silent crimping, designed for high-volume production. Choose between single or twin crimp head configurations, ranging from 30 to 80 tons of crimping force.

All machines are equipped with a large touch-screen HMI for intuitive control, automatic assembly, and adjustable working height frame.

Key features include scanning of production orders, customizable article recipes, and detailed stroke and force verification for both the assembly and crimping cycles. Users benefit from clear graphs, comprehensive parameter control, and customizable settings for each produced part.

The electrical cabinet, located on the machine’s right side, includes a module for internet connectivity and remote support. The work area is well-lit with LED illumination, and safety is ensured through integrated light barriers. A central lubrication system automatically maintains critical components.

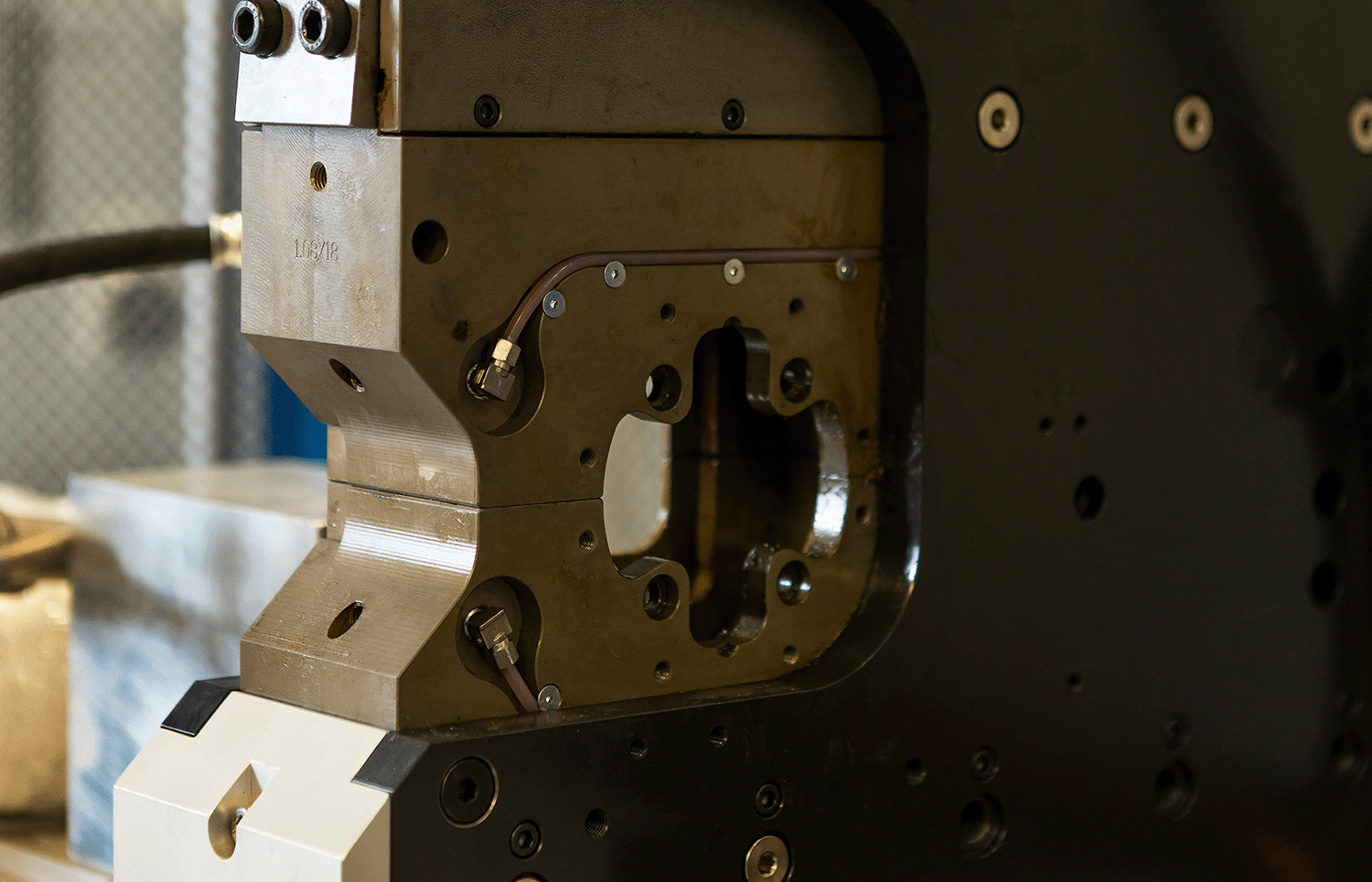

Our PE crimp heads are the smallest and quickest on the market. The narrow crimp head allows for short hoses to be crimped in a twin configuration. In a single crimp head configuration, dual assembly units can be used to automatically position the hose for the next crimp position within the same cycle.

All CRIMPER machines are built for high-volume production and can be equipped with a range of standard accessories to meet your requirements

Crimper CE-30 with closed crimp head

Standard features

| Frame | Fixed or height adjustable working height |

|---|---|

| Crimp head | Open (electric) or closed (electric or pneumatic) |

| CONFIGURATION | Single or Twin crimp head(s) |

| Illumination | LED |

| FORCE ON CRIMP DIES* | 30, 40, 60 or 80 ton equivalent |

| REMOTE SUPPORT | Yes (via ethernet, 3G/4G or WiFi) |

| Stroke & force verification | Yes |

| HMI | ARC ©, 18.5” touch-screen |

| ASSEMBLY | Automatic (max insertion force 3 kN) |

| TOOLING | Exchangeable standard housing with custom dies |

| HOSE CLAMPING | Pneumatic |

| PART FIXTURES | Quick-change with RFID |

| CYCLE TIME | Normally 5-6 seconds incl. assembly |

| SCANNER | Barcode scanner for production orders, etc. |

* Theoretical comparison with conventional machines.

LANTZTECH standard open crimp heads are available with 30, 40, 60 and 80-ton crimp force

ACCESSORIES & EXTRAS

Automatic crimp head positioning system

Automatic fixture positioning system

Scrap box with light barrier verification

Component boxes with camera verification

Label printer

Expansion unit for hose ends

Lubrication unit for couplings

Camera verification system

Hose cutting unit

RFID login

All CRIMPER machines include an automatic assembly unit with stroke and force monitoring

ARC CONTROL SYSTEM

All machines from LANTZTECH use our in-house developed control system, ARC, enabling advanced features in a simple and easy-to-use HMI.

The ARC control system is built on an industrial PC and EtherCAT bus, featuring a large touch-screen display. The HMI presents clear textual and graphical representations of the machine’s operational status and cycle progression. Cycle steps are shown with distinct visual indicators (red/green), giving the operator a straightforward and informative overview.

With ARC, detailed statistics is a standard feature, facilitating in-depth performance monitoring. Furthermore, ARC’s flexible data communication capabilities enable seamless integration with various data management systems.