The APTO Series

CUSTOM MACHINES FOR YOUR INDUSTRY

LANTZTECH has been a trusted provider of customized industrial solutions since the early 1990s, catering to the evolving needs of a broad range of sectors.

The APTO series embodies our dedication to collaborative problem-solving, allowing us to partner with you to overcome technical obstacles of any scale.

We believe in the power of close collaboration, and our in-house experts work alongside you to design and implement complete, effective solutions. LANTZTECH systems are deployed globally, and to ensure uninterrupted performance, each solution is equipped with built-in remote support. This feature provides you with immediate access to expert technical assistance, enabling rapid troubleshooting and minimizing any potential disruptions to your operations, no matter where you are located.

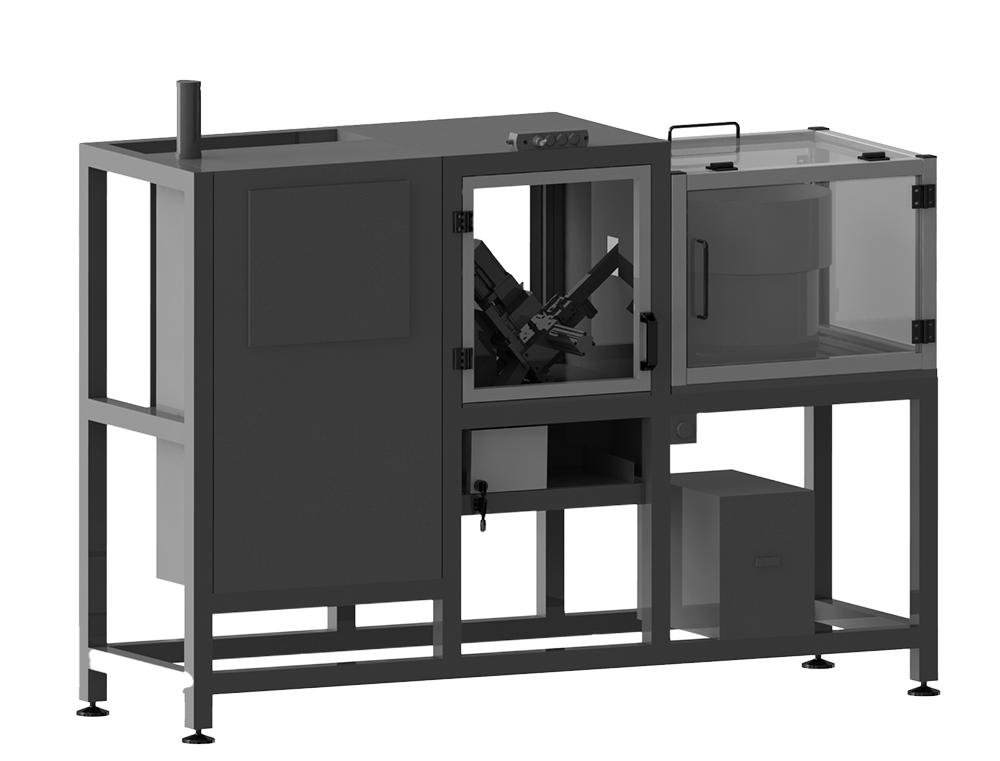

The APTO 3000-VI offers laser scanning, SCARA robots, docking interfaces, shuttles and index tables

The APTO 7000-EL was built to trim, press, weigh and sort molded rubber parts

ARC CONTROL SYSTEM

All machines from LANTZTECH use our in-house developed control system, ARC, enabling advanced features in a simple and easy-to-use HMI.

The ARC control system is built on an industrial PC and EtherCAT bus, featuring a large touch-screen display. The HMI presents clear textual and graphical representations of the machine’s operational status and cycle progression. Cycle steps are shown with distinct visual indicators (red/green), giving the operator a straightforward and informative overview.

With ARC, detailed statistics is a standard feature, facilitating in-depth performance monitoring. Furthermore, ARC’s flexible data communication capabilities enable seamless integration with various data management systems.